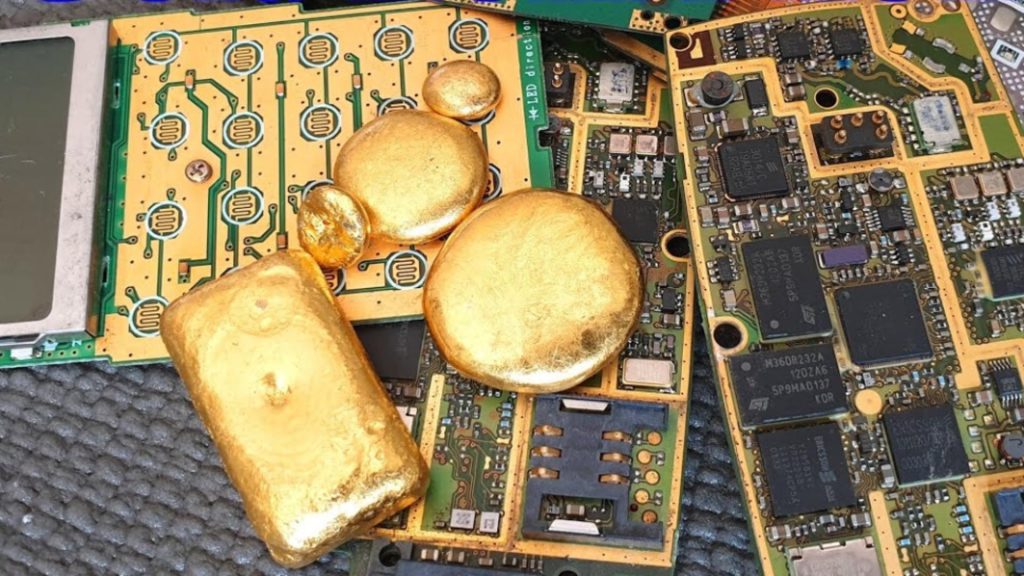

The electronic components we throw away may hide something impressive inside: 22-karat gold. And this is not a metaphor: circuit boards, connectors, and microchips contain small amounts of this metal, which is critical to industry. The question is how to extract it without polluting or spending fortunes.

The answer is beginning to emerge with new recycling methods that avoid cyanide and reduce damage to the environment. Two recent studies show that it is possible to recover high-purity gold using simpler, more selective, and reusable processes.

22-karat gold in the trash: where to find it

The mystery is solved in the circuit boards and contacts of electronic waste. A team from ETH Zurich recovered gold using a protein sponge derived from whey that selectively captures the metal and allows it to be melted down later.

In their tests with computer boards, the scientists obtained a 22-karat nugget from 20 motherboards, demonstrating high purity with a more sustainable process than traditional ones.

Gold in the trash: the Australian method that achieves 99% purity

In Australia, researchers at Flinders University replaced cyanide with trichloroisocyanuric acid (TCCA), a common disinfectant.

With salt water, TCCA dissolves the gold, which is then captured with a highly selective sulfur polymer; when heated or chemically treated, the metal is released in pure form and the material is reused. The results show over 99% purity in tests with complex plates and mixtures, with a workflow that is safer for people and ecosystems.

This is a promising route for recyclers and also for artisanal mining, which still uses mercury. To achieve this, the following steps can be taken:

- Dismantle and crush the plates with gold contacts.

- Leach with TCCA activated in salt water to dissolve the gold.

- Trap the gold in the selective sulfur polymer.

- Release the metal by heating or chemical treatment and melt it.

- Recover and reuse the polymer for new cycles.

Green jobs and the circular economy

For the country, the appeal is twofold: less electronic waste in landfills and more local recovery of critical materials for technology and energy, in line with circular economy goals. Recycling companies and universities already have a scientific roadmap for testing pilot projects.

If these techniques are scaled up, e-waste management could generate jobs in logistics, treatment, and sustainability, as well as reduce metal imports and health risks associated with toxic chemicals.